Iyo PVC floor calendering nzira inoshanda uye inoenderera mberi yekugadzira, iyo inonyanya kukodzera kugadzirwa kwehomogeneous uye permeable chimiro mapepa (akadai sekutengesa homogeneous permeable flooring). Mhedzisiro yaro ndeyekuisa purasitiki iyo PVC yakanyungudutswa kuita yunifomu yakatetepa layer kuburikidza ne-multi-roll calender, wozoitonhodza kuti iite. Aya anotevera ndiwo matanho chaiwo uye akakosha tekinoroji ekudzora mapoinzi:

I. Calender Process

Raw Material Pretreatment > Yakakwira-kumhanya kupisa kusanganisa, kutonhora uye kutonhora kusanganisa, mukati musanganiswa uye plasticizing, kuvhurika kusanganisa uye kudyisa.

Four-roll calendering, embossing/laminating, kutonhora uye kuumba, kudimburira nekumonera

II. Nhanho-ne-nhanho Kushanda Makiyi Mapoinzi uye Tekinoroji Paramita

1. Raw Material Pretreatment uye Kusanganiswa

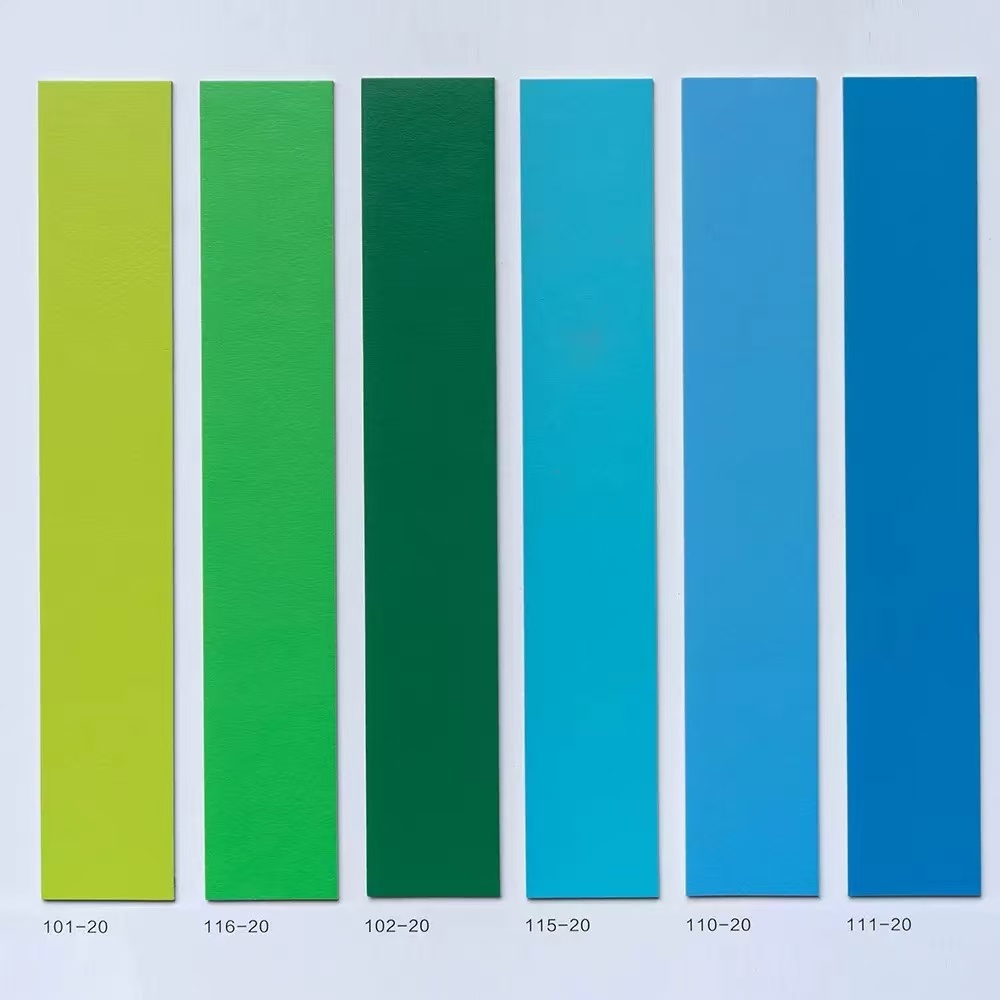

Formula Maumbirwo (Muenzaniso): - PVC resin (S-70 mhando) 100 zvikamu, - Plasticizer (DINP / environmentally friendly ester) 40-60 zvikamu, - Calcium carbonate filler (1250 mesh) 50-80 zvikamu, - Heat stabilizer (calcium zinc composite, 5-5 chidimbu cheasidhi) - 3-5 chidimbu chechidimbu. - Pigment (titanium dioxide / inorganic color poda) 2-10 zvikamu

Kusanganisa Maitiro*:

Kupisa kusanganiswa: High-speed mixer (≥1000 rpm), kupisa kusvika 120 ° C (10-15 maminitsi) kubvumira PVC kutora plasticizer; Cold Mixing: Inokurumidza kutonhora kusvika pasi pe40 ° C (kudzivirira mapundu), kutonhora kusanganisa nguva ≤ 8 maminitsi.

2. Plasticizing uye Kudyisa

- Musanganiswa Wemukati: Kupisa 160-170 ° C, Kudzvinyirira 12-15 MPa, Nguva 4-6 maminitsi → Kugadzira homogeneous rubber mass;

Vhura Musanganisi: Twin-roll tembiricha 165±5°C, Roller Gap 3-5 mm → Cheka kuita mitsetse kuti urambe uchidyisa kucalender.

3. Four-roller Calendering (Core Process)

-Makiyi Tekiniki:

- Roller Speed Ratio: 1#:2#:3#:4# = 1:1.1:1.05:1.0 (kudzivirira kuunganidza zvinhu);

- Mid-Height Compensation: Roller 2 yakagadzirwa ne 0.02-0.05mm korona yekumisa kudziya kwekubhenda deformation. 4. Surface Kurapa uye Lamination

Embossing: Embossing roller (silicone / simbi) tembiricha 140-150 ° C, kudzvinyirira 0.5-1.0 MPa, kukurumidza kunofananidzwa nemutsara wecalendering;

Substrate Lamination (Inosarudzika): Girazi faibha mat / jira risiri rakarukwa, preheated (100 ° C), rakanamirwa nePVC yakanyunguduka pa roller #3 kuwedzera kugadzikana kwedimensional.

5. Kutonhora uye Kuumba

Matanho matatu ekutonhora roller tembiricha:

Tension Control: Kupeta tension 10-15 N/mm² (kudzivirira kutonhora shrinkage uye deformation).

6. Kucheka uye Kupeta

- Laser Online Ukobvu Kuyera: Chaiyo-nguva mhinduro inogadzirisa iyo roller gap (kurongeka ± 0.01mm);

-Otomatiki Kuchekwa: Zvimedu hupamhi ≤ 20mm, yakadzokororwa uye pelletized kuti ishandiswezve;

- Kupeta: Kugara kutenderedza pakati pepakati, roll dhayamita Φ800-1200mm. III. Maitiro Matambudziko uye Solutions

1. Hukobvu Husina Kuenzana. Chikonzero: Roller Temperature Fluctuation > ±2°C. Solution: Yakavharwa-Loop Thermal Oiri Temperature Control + Close-Drilled Roller Cooling.

2. Surface Gasi. Chikonzero: Kusakwana Kusanganisa Degassing. Solution: Vacuum the Internal Mixer (-0.08 MPa).

3. Edge Cracks. Chikonzero: Kunyanya Kutonhodza / Kunyanya Kushushikana. Solution: Deredza Mbero-End Kutonhora Kunyanya uye Wedzera Inononoka Kutonhora Zone.

4. Muenzaniso Die. Chikonzero: Kusakwana Embossing Roller Pressure. Mhinduro: Wedzera iyo Hydraulic Pressure kusvika 1.2 MPa uye Geza iyo Roller Surface.

IV. Zvakatipoteredza Hushamwari uye Mafambiro Akakwidziridzwa Maitiro

1. Inotungamira-Yemahara Stabilizer Kutsiva:

- Calcium-Zinc Composite Stabilizer + β-Diketone Synergist → Inopfuura EN 14372 Migration Test;

2. Plasticizer Inoshamwaridzana Nezvakatipoteredza:

- DINP (Diisononyl Phthalate) → Cyclohexane 1,2-Dicarboxylate (Ecoflex®) Inoderedza Ecotoxicity.

3. Kudzokorodza tsvina:

-Kupwanya zvimedu → Kusanganisa nezvinhu zvitsva pachiyero che ≤30% → Inoshandiswa mukugadzirwa kwepasi.

V. Calendaring vs. Extrusion (Application Comparison)

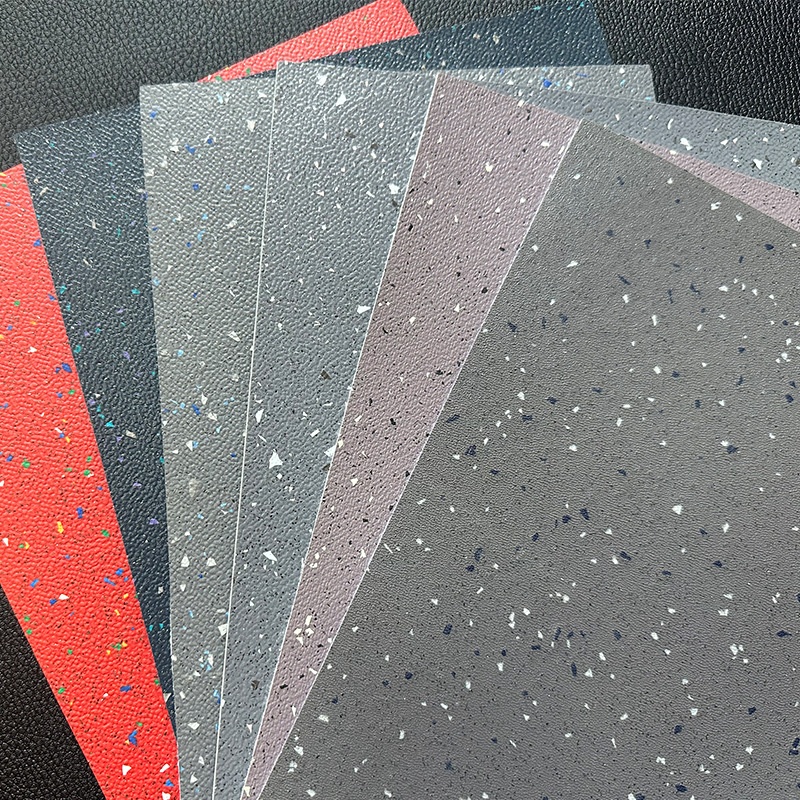

Chigadzirwa Chimiro: Homogeneous perforated flooring/Multi-layer composite, Multi-layer co-extrusion (kupfeka-resistant layer + foam layer)

Hukobvu Range: 1.5-4.0mm (Kururama ±0.1mm), 3.0-8.0mm (Kururama ±0.3mm)

Surface Pedzisa: Yakakwira gloss / Precision embossing (huni tsanga yekutevedzera), Matte / Rough magadzirirwo

Zvakajairwa Zvishandiso: Homogeneous perforated flooring muzvipatara nemarabhoritari, SPC inopindirana pasi pedzimba.

Pfupiso: Iko kukosha kweiyo nzira yecalendering iri mu "high precision" uye "high consistency"

- Maitiro Zvakanakira:

- Precision roller tembiricha yekudzora → Hukobvu kusiyanisa coefficient <1.5%;

-In-line embossing uye lamination → Wana matombo / simbi yekuona maitiro;

- Inoshanda Zvigadzirwa:

Homogeneous perforated PVC flooring ine yakakwirira dimensional kugadzikana zvinodiwa (seTarkett Omnisports series);

-Kuvandudza Sarudzo:

-Akangwara Kudzora: AI-powered dynamic roller gap kugadzirisa (chaiyo-nguva ukobvu mhinduro);

-Kudzoreredza Kwesimba: Kutonhora kwetsvina yemvura kupisa kunoshandiswa kune mbishi preheating (kuchengetedza 30% simba).

> Cherechedza: Mukugadzirwa kwechokwadi, kutonhora kwecalendering uye roller speed kunofanira kugadziriswa maererano ne formula fluidity (melt index MFI = 3-8g / 10min) kudzivisa kuparara (yellowing index ΔYI <2).

Nguva yekutumira: Jul-30-2025